High Precision Direct Square Roll Forming Machine ERW Square Tube

Mill

The high-frequency pipe production line is specialized equipment to

produce high frequency straight seam welded pipes for

structuralpipe and industrial pipe with 40mm×40mm -90mm×90mm and

wall thickness of 1.5mm-4.0mm.

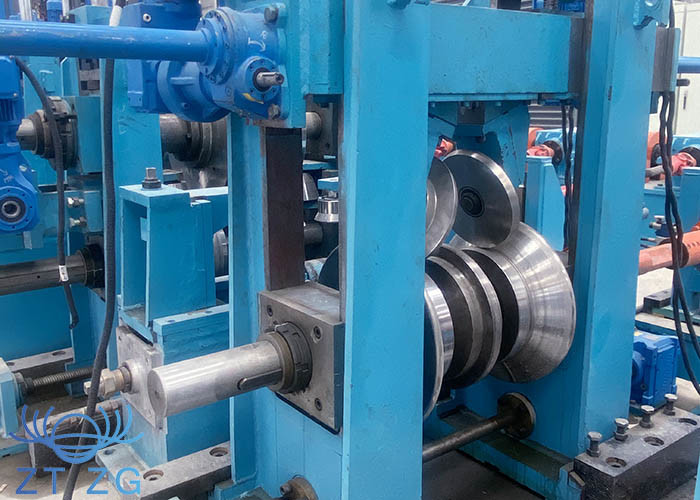

Direct Square to Square Pipe Mill/Tube Mill

Compare with round into square&rectangle forming way,this way

is better for the shape at the edge of cross section,comparatively,

semi-diameter of inner arc is Small, and the brim is flat, outlook

is regular.

It is directly roll the steel strip and bend it to square &

rectangular shape, then weld it to finish the formation.

Characteristics and Advantages:

1).Compare with round into square&rectangle forming way,this

way is better for the shape at the edge of cross

section,comparatively, semi-diameter of inner arc is Small,and the

brim is flat,outlook is regular.

2).the whole line load is low ,especially the sizing parts.

3).The width of steel strip is small about 2.4-3% than round into

square & rectangle,it can save the consume of raw material.

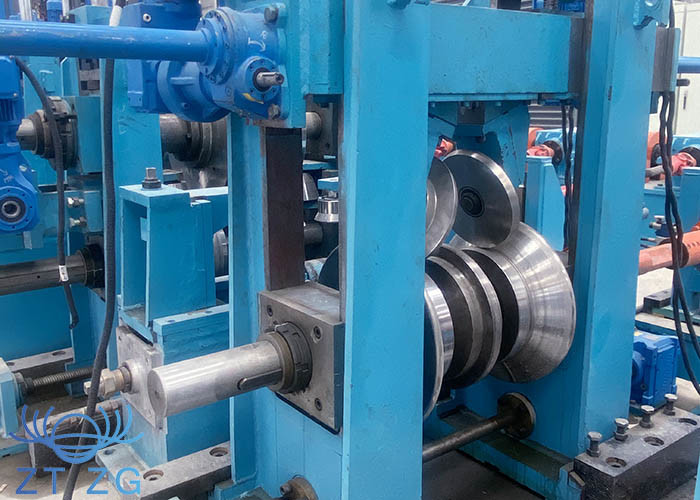

4).It adapt the multi-point bending way, avoid the axial force and

side abrasion, reduce the forming step while ensure the

quality,meanwhile it reduce the power wastage and roller abrasion.

5).It adapt the combined type roller on the most of the stands,it

realize that one set of roller can produce dozens of

square&rectangle pipe with different specification,it decrease

the store of roller,low the cost about 80% on roller, Fast the

bankroll turnover, short the time one new product design.

Basic Technical Information of Welded Pipe Production LineProduct&yield | Round Pipe | 48mm-114mm Thickness:1.5mm-4.5mm |

| Square & rectangle tube | 40mm×40mm -90mm×90mm Thickness:1.5mm-4.0mm |

Length | 6m-12m Length Tolerance: ±3mm |

Production Speed | 20-65 m/min |

Production capacity | 30,000ton/year |

Consumption | Mill installed capacity | 160 kw |

Line Area | 78m(length) ×6m (width) |

worker | 6-8 workers |

Raw Material

| Carbon Steel coil | Q235B(ASTM GR·D,σs 230) |

Width | 150mm-360mm Thickness: 1.5mm-4.5mm |

Coil ID | 550-610mm |

Coil OD | Max 1600mm |

Coil Weight | 4.0t |

Technical flow

Scrolling up→ Uncoiling → Shear and Welding→ Spiral accumulator→

Forming → H.F. induction welding→ External burr removing→ Cooling →

Sizing→ Flying saw → Run out table →Inspecting→ Packing→ Warehouse

Forming processRound pipe | Cold roll forming process | Good roller design |

ZTF forming process | Save alt least 60% roller cost with electric control adjustment |

Square & rectangular pipe | General round-to-square process | Stable forming process |

Round-to-square with turkshead | Good pipe quality |

Process of directly square-to-square(DSS) | One set of roller can produce all tubes with electric control and

automatic adjustment |

We can design and manufacture square tube machine according to

customer’s requirement.