Crane Span Structure Cold Forming Sectional Steel Cold Rolled Steel

Machine

Function and Structure

Cold rolling steel equipment series is according to the different

needs of customers, through the method of cold rolling various

shapes of steel. The generalized cold-formed steel equipment

includes open-end cold-formed steel equipment and closed-end

cold-formed steel equipment. The cold-formed steel section

equipment introduced here refers to open-formed cold-formed steel

section equipment.

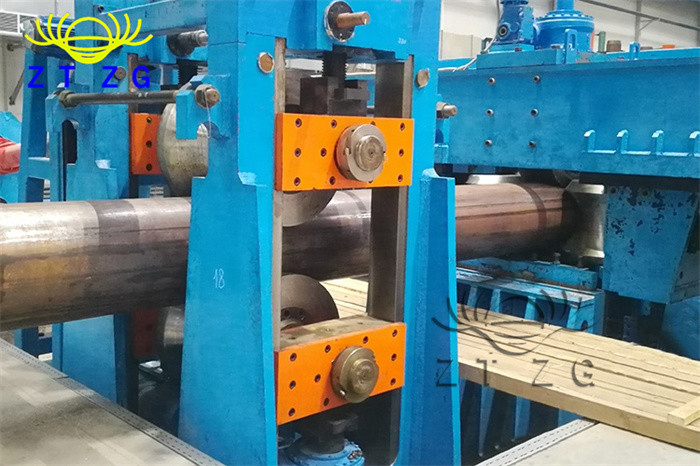

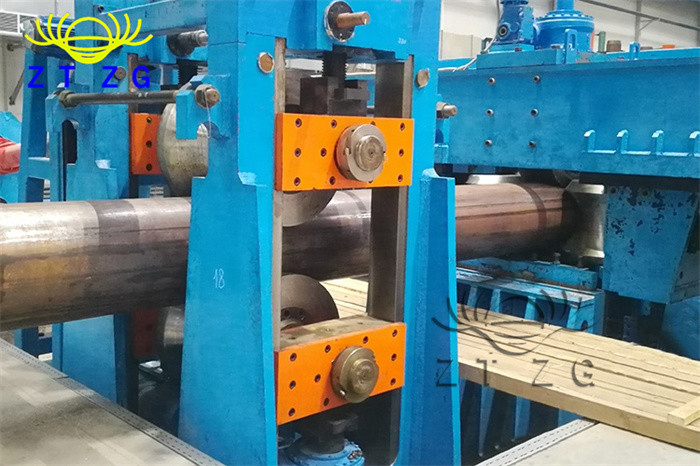

Function and structure:

The molding of profiles of various specifications, using

independent casting frame (tempering treatment), base using welding

structure, after stress removal treatment. The molding machine

adopts an independent archway structure, universal joint shaft

drive. Inlet guide device; High-quality carbon steel roller; It is

easy to adjust and operate. Roller process design using imported

software, computer design.

Step1: Uncoiler

Uncoiler the function is to support and expand the strip, so strip

can enter into machine to roll forming. Strip can be expanded by

hydraulic or pneumatic and uncoiler can be rotated 180 degree.

Strip expand speed can be adjusted, braking device designed with

pneumatic or hydraulic cylinder to press the brake rubber block

Step2: Shear & end welding

It is used to shear the head and the end of the steel strip of two

steel coils, cutting off the irregular part then welding two steel

strips, so machine can work continuously.

Step3: Accumulator

Installed between shear & end welder and forming mill, horizontal

spiral accumulator store a large amount of strip in a reasonable

footprint space to give enough time for shear & end welder to cut

and join the ends of two successive coils with non-stop tube mill

It has vertical cage type accumulator for small size tube mill

Step4: Forming

The function of this part is to make the steel strip become to the

tube blank by forming rollers

Step5: welding & scarfing

The function of this part is to center the welding seam and guide

the tube blank to welding device, so the welding seam will be

closed before welding, use scarfing tool to remove the burr to

ensure the smooth welding

Step6: Sizing

The function of this part is used to finish the tube blank from the

forming machine, so the tube size can meet the physical dimension

as customer required, form to square and rectangular and other

shape profiles

Step7: Straightening

4 rolls turk head straightening, straighten pipe online to achieve

the ideal flatness

Step8: Cut off saw

Cut off the pipe with required length, length of pipe can be set

With option of cold saw and flying saw

Step9: Run out table

This unit is to convey the finished pipe to packing, pipe transmit

by dynamic roll. A signal sensing device installed in the end of

run out table, when pipe touch the signal sensing device, it will

feedback the signal to control panel, control panel start working

and discharge the pipe

Advantage

Cold Rolled Steel Machine. It can produce all kinds of cold-formed

steel products with a circumference of 2200mm, such as a square

tube, open section steel, irregular section steel, etc. The

thickness of finished products is 22mm max, and the material is

Q345 (or customized)

Operation

By Just Pressing the Button

Easy to restore rolls.

2.4-3% strip width shrinkage than round square forming method, so

saving more raw materials

Simple abroach cold rolled section steel such as directly formed

channel steel, C shaped steel, Z shaped steel. The rolls can be

shared with directly square forming technology.

ZTZG Company Introduction

FAQ

Q: Are you a manufacturer?

A: Yes, we are a manufacturer. We have 4 factories ( Machining,

Assembling, Heat treatment, and Moulding ). We also have our own

R&D department. Welcome to visit us.

Q: What kind of payment term do you do?

A: We do T/T.

Q: What info do you need before giving me the price and proposal?

A: Since we design individual machines based on our customer's

requirements, we need your desired products' basic dimensions,

including all the pipe diameter(or tube length), thickness range,

usage, raw material steel grade, coil weight, and degree of

automation.

Q: What should I do if I just start a new business?

A: Contact us immediately, we provide a free consultant for

pre-sales service. Also, we can help you solve the raw material

(steel coil) purchase, worker training, international market price,

and more.

Q: How do you do QA?

A: We have a special team to do strict QA, this is one of our

strengths:

(1)Every gearbox will be tested for 8 hours with oil inside to

guarantee there is no leak.

(2)Every shaft will be inspected for centering jumpiness.

(3)Every roller will be checked to make sure it's in the range of

tolerance critical parts will be inspected for all dimensions.

Q: Why I should choose you? what are the differences between you

and other Chinese suppliers?

A: We are concentrating on pipe-making machines for more than 20

years. We have constructed many steady trading partners in Asia,

Africa, the middle east, Europe, and South America throughout the

years. Our innovative designed production line and every single

unit of the production line are economical and practical.

Model List |

Model | Width

mm | Square pipe

mm | Thickness

mm | Working spead

m/min |

LW100 | 40-100 | 10x10-25x25 | 0.5-2.0 | 20-80 |

LW200 | 80-200 | 20x20-50x50 | 1.0-3.0 | 20-80 |

LW400 | 200-400 | 50X50-100X100 | 2.0-5.0 | 20-60 |

LW600 | 240-600 | 60X60-150X150 | 2.0-7.0 | 20-60 |

LW800 | 320-800 | 80X80-200X200 | 2.5-10.0 | 20-40 |

LW1050 | 400-1050 | 100X100-250X250 | 3.0-12.7 | 15-30 |

LW1250 | 480-1250 | 120X120-300X300 | 3.0-14.0 | 10-25 |

LW1400 | 600-1400 | 150X150-350X350 | 4.0-16.0 | 8-20 |

LW1600 | 800-1600 | 200X200-400X400 | 6.0-18.0 | 8-15 |

LW2000 | 1000-2000 | 250X250-500X500 | 6.0-20.0 | 8-15 |

LW2200 | 1100-2200 | 280X250-550X550 | 6.0-22.0 | 8-15 |