Welding Tube Making Machine Carbon Steel Plc Control Steel Pipe

Production Line

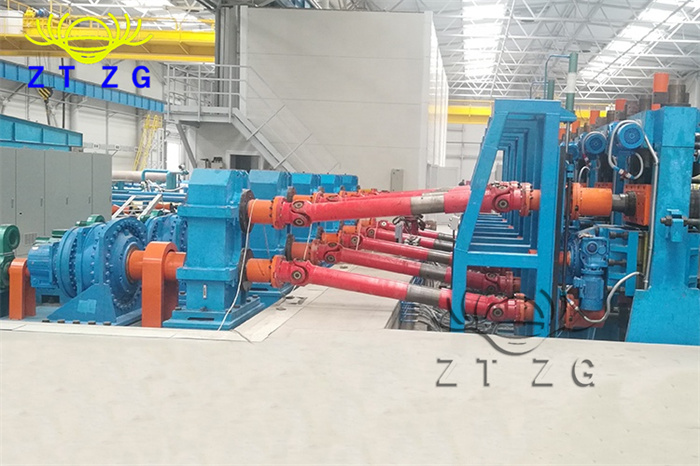

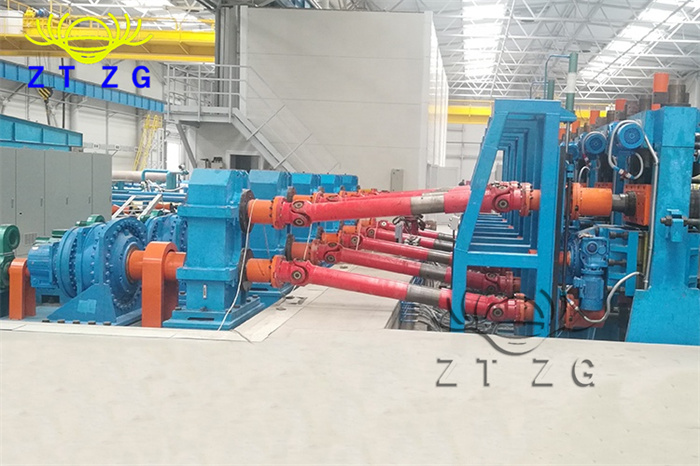

Machine Introduction

High-frequency welded pipe machinery is the production of low

carbon low alloy steel material welded pipe special equipment, the

specifications of the steel belt feeding machine will do the trick,

by forming roller steel with curled up into a tube, then using

high-frequency proximity effect and skin effect for tube side heat

quickly to welding temperature, and under the squeezing roller

extrusion complete welding, then through cooling, Sizing and

roughing to the required size of steel pipe.

can produce X80, J55 API oil casing, oil, and gas pipe, in line

with API-5L, API-5CT, and other standards. The unit can also

produce special special-shaped tubes for air-cooled island

condensers used in power plants and steel mills.

Product parameters

| Product model: | DLW800(200 square) square tube equipment |

| Finished pipe diameter (mm): | square pipe 80×80-200×200, round pipe φ108-φ219 and the

corresponding size of rectangular pipe |

| Finished steel tube wall thickness (mm) : | 3-8.0 |

| Material: | б B ≤580Pnб S ≤350MPa carbon steel and low alloy steel: б B ≤580Pnб

S ≤350MPa |

| The production speed of welded pipe unit (m/min): | 10-35 |

| Power of main motor (KW): | 486 |

| Hf power (kW) : | 600 |

Application

Galvanized welded steel pipe for low-pressure fluid transportation

(GB/T3091-2008) is also known as galvanized welded steel pipe,

commonly known as a white pipe. It is used for conveying water,

gas, air oil, heating steam, warm water, and other general

low-pressure fluid or other purposes of hot-dip galvanized welded

steel pipe (furnace welding or electric welding). The wall

thickness of steel pipe is divided into ordinary galvanized steel

pipe and thickened galvanized steel pipe. Nozzle end form is

divided into galvanized steel pipe without thread and galvanized

steel pipe with thread. The specification of steel pipe is

expressed in nominal caliber (mm), which is an approximation of the

inside diameter. It is customary to use inches, such as 1/2, 3/4,

1, 2, etc.

ZTZG Company Introduction

FAQ

Q: Are you a manufacturer?

A: Yes, we are a manufacturer. We have 4 factories ( Machining,

Assembling, Heat treatment, and Moulding ). We also have our own

R&D department. Welcome to visit us.

Q: What kind of payment term do you do?

A: We do T/T.

Q: What info do you need before giving me the price and proposal?

A: Since we design individual machines based on our customer's

requirements, we need your desired products' basic dimensions,

including all the pipe diameter(or tube length), thickness range,

usage, raw material steel grade, coil weight, and degree of

automation.

Q: What should I do if I just start a new business?

A: Contact us immediately, we provide a free consultant for

pre-sales service. Also, we can help you solve the raw material

(steel coil) purchase, worker training, international market price,

and more.

Q: How do you do QA?

A: We have a special team to do strict QA, this is one of our

strengths:

(1)Every gearbox will be tested for 8 hours with oil inside to

guarantee there is no leak.

(2)Every shaft will be inspected for centering jumpiness.

(3)Every roller will be checked to make sure it's in the range of

tolerance critical parts will be inspected for all dimensions.

Q: Why I should choose you? what are the differences between you

and other Chinese suppliers?

A: We are concentrating on pipe-making machines for more than 20

years. We have constructed many steady trading partners in Asia,

Africa, the middle east, Europe, and South America throughout the

years. Our innovative designed production line and every single

unit of the production line are economical and practical.