Low Carbon Steel Api Tube Mills

Description

The whole production line adopts "ZTF forming technology which is

developed by ourselves combined with advanced Japanese

FFXtechnology. ( lt is no need to change rollers in the breakdown

section) API tube mill is specialized for manufacturing welded

tubes for petroleum and gas tube lines. Taking hot-rolled steel as

raw material, it produces required tubes through cold roll forming

and suitable welding methods like H.F. welding, submerged arc

welding, and so on.

Equipment Advantages

√ When producing round pipe, it can utilize ZTF forming technique

√ When producing square & rectangular tube, it can utilize directly

square-square (DSS) technique

Product Parameter

Product&yield | Round Pipe | OD:325-660MM Thickness:6-20MM |

Length | 6m-12m Length Tolerance: ±3mm |

Production Speed | 20-50m/min |

Production capacity | 30000 Ton |

Consumption | Mill installed capacity | 300kw |

Line Area | 40x10m |

worker | 6-8 worker |

Raw Material | Carbon Steel coil | x70 N80 |

Width | 1025mm-2100mm Thickness:6-20MM

|

Application

Widely used as the architectural structure tubes, low-pressure

liquid tubes, coal transmission belt tubes, driveshaft tubes,

guardrail tubes, tower footing tubes, automobile beam steel tubes,

and other products.

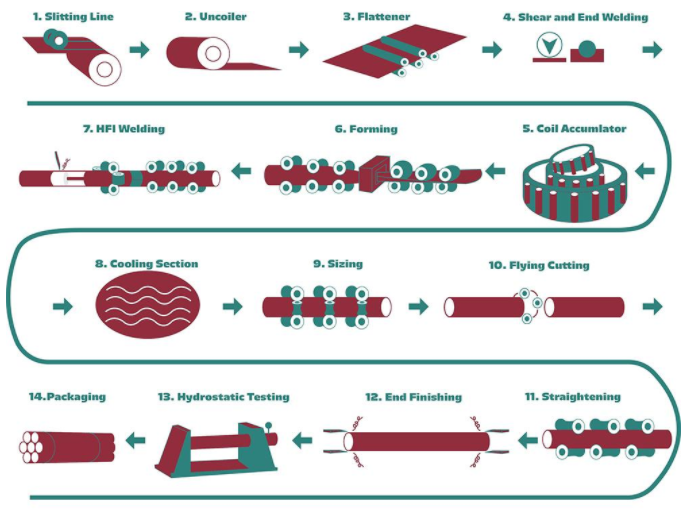

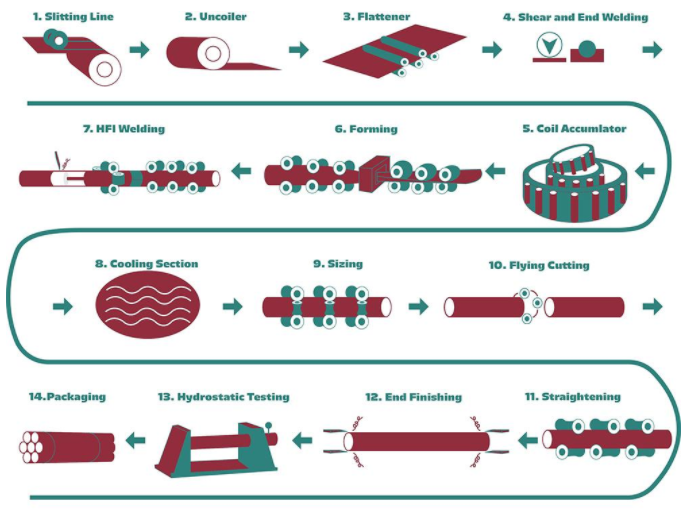

Process Flow

Scroll up→ Uncoiler→ Straightening end→ Flattener→ Auto-Shear and

Welding→ Horizontal Accumulator→ Strip UT→Forming(ZTF) → H.F.

induction welding→ Removing external burr→ Removing inner burr→

Burnishing→ Online Detection→ Seam annealer→ Air cooling→ Water

cooling→ Sizing→ Cut off→ Roll table→Flattening Test→ End-facing

and chamfering→ Hydrostatic test→Off-line UT test→ Drifter→

inspection→Weighing and length measurement → Coating & Printing→

Packing→ Warehouse

After Sales Service

1. Marketing plan and support.

2. Technical explanation and solution developing

3. Company visit reception

4. Contract tracking and delivery

5. Technical personnel training

6. On-site equipment installation and commissioning guidance

7. 7×24 continuous troubleshooting

Our company

FAQ

Q: Are you a manufacturer?

A: Yes, we are a manufacturer. We have 4 factories ( Machining,

Assembling, Heat treatment, and Moulding ). We also have our own

R&D department. Welcome to visit us.

Q: What kind of payment term do you do?

A: We do T/T and L/C.

Q: What info do you need before giving me the price and proposal?

A: Since we design individual machines based on our customer's

requirements, we need your desired products' basic dimensions,

including all the pipe diameter(or tube length), thickness range,

usage, raw material steel grade, coil weight, and degree of

automation.

Q: What should I do if I just start a new business?

A: Contact us immediately, we provide a free consultant for

pre-sales service. Also, we can help you solve the raw material

(steel coil) purchase, worker training, international market price,

and more.

Q: How do you do QA?

A: We have a special team to do strict QA, this is one of our

strengths:

(1)Every gearbox will be tested for 8 hours with oil inside to

guarantee there is no leak.

(2)Every shaft will be inspected for centering jumpiness.

(3)Every roller will be checked to make sure it's in the range of

tolerance critical parts will be inspected for all dimensions.

Q: Why I should choose you? what are the differences between you

and other Chinese suppliers?

A: We are concentrating on pipe-making machines for more than 20

years. We have constructed many steady trading partners in Asia,

Africa, the Middle East, Europe, and South America throughout the

years. Our innovative designed production line and each unit of the

production line practical.