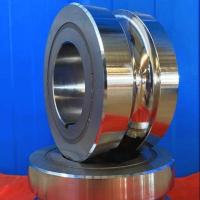

Pipe Making Machine Round Roller/Square Roller

Product Description

Welded pipe mould tube roller die is a necessary hardware accessory

for manufacturing metal straight seam welded pipe. Under the action

of the external force of the welded pipe mould, the steel coil is

gradually forced to be cold rolled and curled in the arc of the

tube roller, and then welded to obtain the closed welded pipe.

Strong Hot Sell Point

The welded pipe mold is widely used in the production of decorative

pipes, industrial pipes, ERW welded pipes and other pipes.

Product Process

Cutting → Rough Machining → Quenching and Tempering → Finishing →

Heat Treatment (High Temperature Quenching and High Temperature

Tempering) → Polishing → Finished Product

Heat Treatment Way

There are four heat treatment way for your choose.

(1) Vacuum Heat Treatment :HRC 61-63

(2) Black treatment: HRC61-63

(3) Nit riding treatment: HRC61-63

(4) Vacuum Gas Quenching and Subzero Heat Treatment:HRC63-65

Warm reminding: Tube diameter≥133mm, HRC:58-61

Different heat treatment way , different price!

Material Description

| Material | Cr12MoV / Cr12 |

| Brand Name | ZTZG |

| Type | Extrusion Die |

| Shaping Mode | Forming Roller |

| Hardness | HRC58~65 |

| Application | ERW tube mill |

| Service Life | ≥10 years |

| Quality | High Grade |

| Weight | Depending on Pipe Size |

| Package | Wooden Case |

Different Kinds

Tube Roller Packing

(1)Rust proof oil should be added to the export tube roller mould

before removing the stains.

(2)Packing in wooden boxes, lined with paper and cloth , to avoid

bruising ,then use shockproof membrane.

(3)The most outboard wooden packing , all the goods shipped by sea

require fumigation wooden boxes.

About Us

Why Choose Us

Q:Are you manufacturer?

A:Yes,we are manufacturer. We have 4 factories ( Machining,

Assembling, Heat treatment, and Moulding ). We also have our own

R&D department. Welcome to visit us.

Q:What kind of payment term do you do?

A: We do T/T and L/C.

Q:What info do you need before giving me the price and proposal?

A: Since we design individual machine based on our customer's

requirement, we need your desired products' basic dimension,

including all the pipe diameter(or tube length), thickness range ,

usage, raw material steel grade, coil weight, and degree of

automation.

Q: What should I do if I just start a new business?

A:Contact us immediately ,we provide free consultant for pre-sales

service .Also we can help you solve the raw material (steel coil)

purchase, worker training, international market price, and more.

Q:How do you do QA?

A:We have special team to do strict QA,this is one of our

strengths:

(1)Every gear box will be tested for 8 hours with oil inside to

guarantee there is no leak.

(2)Every shaft will be inspected for the centering jumpiness.

(3)Every roller will be checked to make sure its in the range of

tolerance critical parts will be inspected for all dimensions.

Q:Why I should choose you? what are the differences between you and

other Chinese suppliers?

A:We are concentrate on pipe making machines for more than 20

years. We have constructed many steady trading partners in

Asia,Africa, middle east, Europe, and South America throughout the

years. Our innovative designed production line and each single unit

of the production line are not only economical but also practical.