Green Carbon Steel Drain Pipe Easy To Operate Square Pipe Mill

ERW Tube Mill with Turks-head Forming Technique Introduction:

Advantage of Turks-head Forming Technique:

1. Save rollers: part of the molds can be commonly used. Especially

for square & rectangular pipe.

2. The Turks - head can be rotated, so the welding seam can be put

in any position of the pipes.

3. It can prevent the surface of pipe from scratching.

4. The max thickness of the round pipe and square pipe can be same.

(The upper limit of thickness for square pipe is always 1 mm

less than round pipe's using round-to-square forming method)

5. The production shape is much better, the shape of square &

rectangular pipe is very neat.

6. The Turks - head put 4 sides of force on the pipe at same time,

which can reduce the wear and tear of the mill, protect the tube

mill,increase the using life.

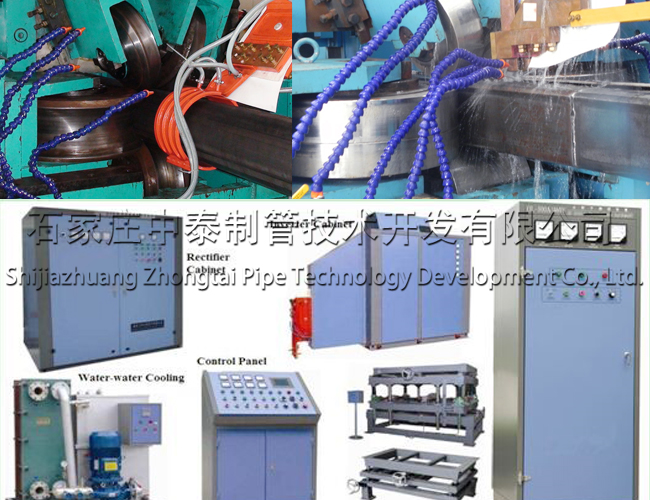

Technical flow

Scrolling up→ Uncoiling → Shear and Welding→ Spiral accumulator→

Forming → H.F. induction welding→ External burr removing→ Cooling →

Sizing→ Flying saw → Run out table →Inspecting→ Packing→ Warehouse

Square Tube Mill Auxiliary Machines:

Customers can trust us to buy the auxiliary machines. Our choice of

suppliers for the auxiliary parts is made after 22 years of

experience.

Un-coiler

Function: Used for supporting strip steel coil and open it as strip steel so

as to make preparation for the pipe forming process.

Shearing butt welding

2 Types: Automatic & Manual

Function: Shear & end welder parallel cuts the head of the strip coming out

of uncoiler and the tail of the strip steel going into the

accumulator, and weld them together to form a smooth and continuous

line of strip steel.

Strip Accumulator

Function: Accumulator is used to accumulate strip steel from uncoiler and

provide strip steel to forming unit. It leaves time for the shear &

end welder for strip welding and stores certain amount of strip for

continuous forming.

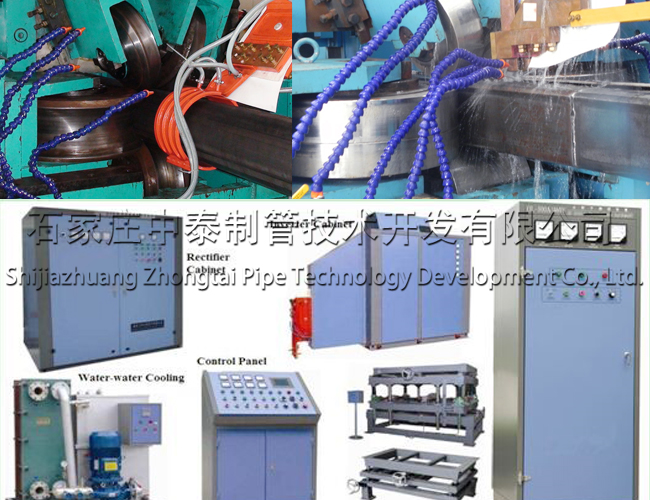

Solid State High Frequency Welder

Function: The welder is used for welding edge heating with high-frequency

heating device. The whole set of solid-state H.F welder comprises

of rectifying cabinet, inverter, output cabinet, connecting optical

fiber, closed loop water cooling system, central operator console,

and mechanical adjustment device.

Saw Cutting System

Function: Flying saw is used to cut tube during static and motion status in

continuously production into desired length.

Production Process